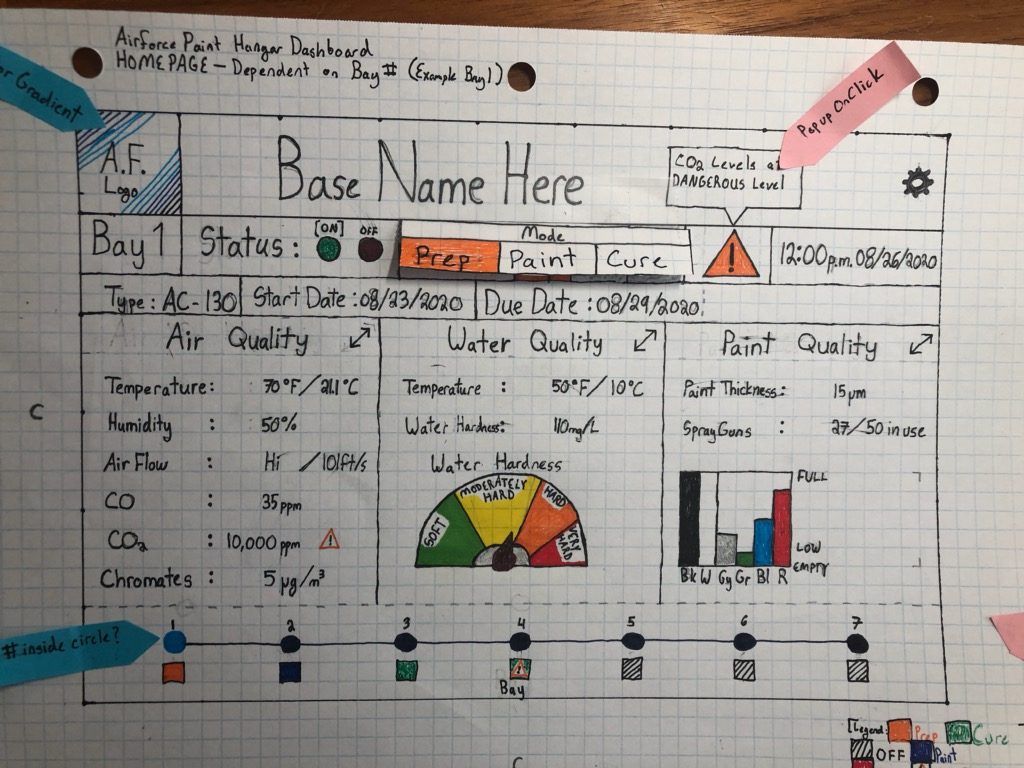

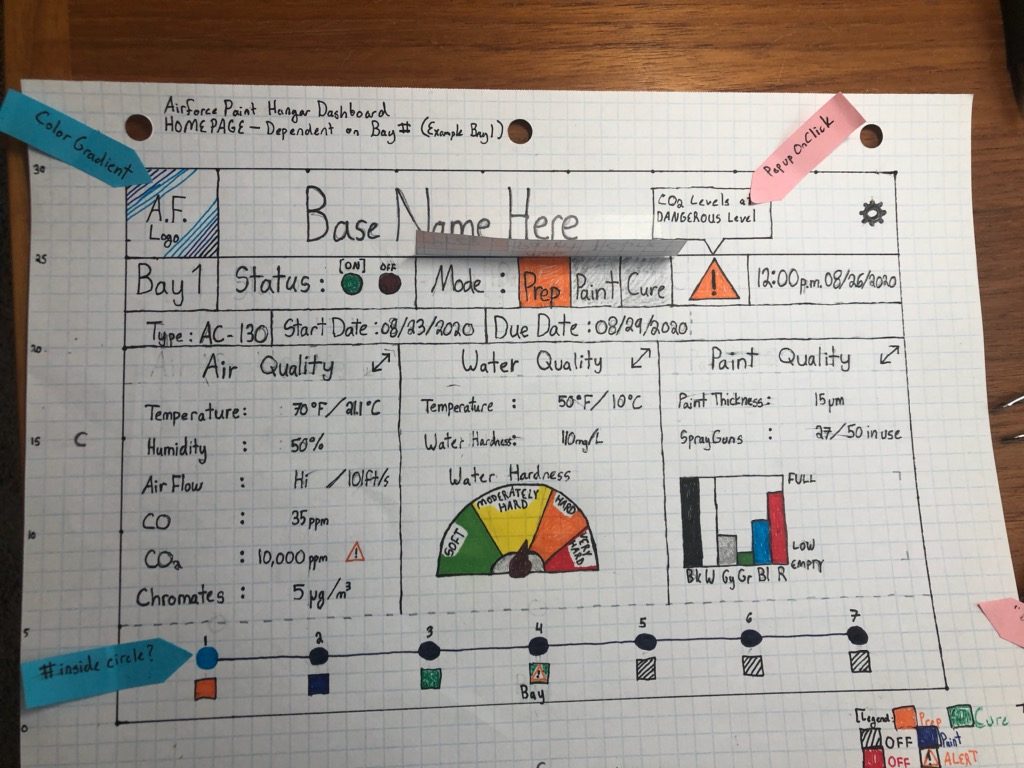

Air Force Paint Hangar Analytics Dashboard Demo showcasing Air Quality + Water Quality visual graphics in Bay 1, as well as unique UIs in other Bays. The goal of this project was to upgrade the current system at AF Paint Hangar with an improved dashboard that allows workers to monitor the hangar in its entirety. From monitoring temperature, humidity – to being able to get alerts for Carbon Monoxide levels being too high. Using ThingWorx, it provides the ability to monitor, control, automate and optimize the overall business process. Easy to use Mashup that quickly displays data from smart connected products. Highly Flexible, fast turn around with binding properties to widgets and very intuitive.

The operations center of large paint hangers needs continuous understanding of what is going on in the environment as prep and painting are being done. Whether cleaning, sanding or painting, it is critical to monitor the environment to ensure worker safety.

We are modeling IoT sensors to monitor environmental factors of a paint hanger to determine if the building is within safe parameters and will not harm workers. This includes writing software code to simulate data points, running applicable simulations, and creating data visualizations, which provide an opportunity for predictive analytics in the future.

Benefits/Outcomes

Monitor environment to give warnings and alerts at appropriate times

- Airflow during cleaning and sanding

- Fan sensors in fans to determine air quality being filtered out of the building

- Chemicals in the air to ensure regulations are adhered to, when masks should be worn, etc.

- Temperatures in boilers that heat the water

to clean and paint

Toolbox

- Software: PTC ThingWorx

- Use case: An Air Force paint hanger (a very large building, holding up to four C-5 aircrafts)

Wireframes for Paint Hangar. Software Used: Adobe XD.